PVDF Plastic Sheet – High Performance Solution for Chemical and Industrial Applications

PVDF plastic sheet (Polyvinylidene Fluoride sheet) is a high-performance thermoplastic material widely used in harsh chemical environments and high-purity applications. Known for its excellent chemical resistance, mechanical strength, and thermal stability, PVDF sheets are an ideal choice for industries such as chemical processing, electronics, pharmaceuticals, and semiconductor manufacturing.

✅ What Is PVDF Plastic Sheet?

PVDF plastic sheet is made from polyvinylidene fluoride, a semi-crystalline fluoropolymer with outstanding resistance to aggressive chemicals, UV radiation, and high temperatures. It maintains excellent performance in both indoor and outdoor environments.

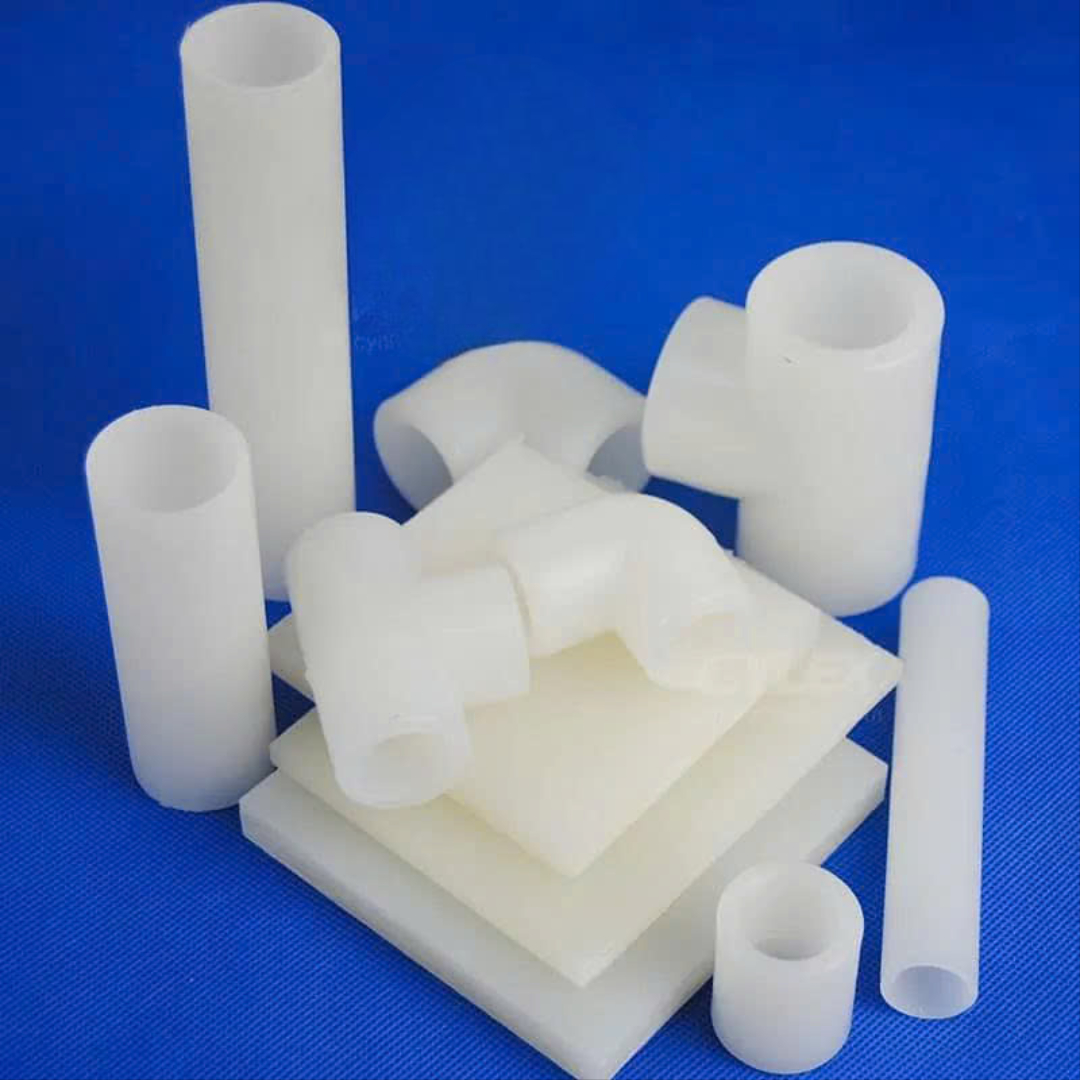

These sheets are typically opaque white or translucent, available in various thicknesses and sizes to suit different applications.

Key Features and Benefits

Exceptional Chemical Resistance

Resists strong acids, bases, solvents, and chlorine-based compounds.️ High Temperature Tolerance

Continuous working temperatures up to 140°C (284°F).High Purity & Low Contamination

Suitable for ultrapure water systems and cleanroom applications.Mechanical Strength & Rigidity

Maintains dimensional stability even under mechanical stress.☀️ UV & Weather Resistant

Suitable for both indoor and outdoor use without degradation.Easy to Fabricate and Weld

Compatible with thermoforming, welding, and CNC machining.

Common Applications of PVDF Sheets

PVDF plastic sheets are widely used across industries such as:

Chemical Processing Plants – Lining tanks, vessels, and scrubbers

Pharmaceutical & Biotech Facilities – Cleanroom walls and protective barriers

Semiconductor Industry – Ultra-pure chemical delivery systems

Food & Beverage Industry – Contact-safe surfaces

Water Treatment Systems – Acid/alkali-resistant panels and supports

Electrical & Electronics – Insulation panels, housings, and dielectric components

Available Sizes & Formats

PVDF sheets are commonly available in:

Thickness: 1mm to 50mm

Width: Up to 1220mm (48″)

Length: Up to 2440mm (96″) or custom cut

Color: Natural white (standard), black (UV stabilized)

You can also request machined PVDF parts or custom-cut sheet panels for specific projects.

Comparison: PVDF vs Other Plastics

| Property | PVDF | PTFE | PVC | PP |

|---|---|---|---|---|

| Chemical Resistance | Excellent | Excellent | Moderate | Good |

| Temperature Limit | 140°C | 260°C | 60°C | 100°C |

| Mechanical Strength | High | Low | Medium | Medium |

| Fabrication Ease | Good | Difficult | Easy | Easy |

| UV Resistance | Excellent | Excellent | Poor | Poor |

Why Choose PVDF Sheets?

If your application requires a durable, chemical-resistant, and high-purity plastic material, PVDF sheets offer the perfect combination of performance and processability. Whether for tank lining, lab equipment, or high-end fabrication, PVDF ensures long-term reliability in the most demanding environments.

Where to Buy PVDF Plastic Sheets?

PVDF sheets are available through industrial plastic suppliers, chemical equipment distributors, or specialty fabrication companies. Ensure materials are virgin-grade and certified for chemical or food-grade use where applicable.

Related products

PLASTIC PIPE

PLASTIC PIPE

PLASTIC PIPE

PLASTIC PIPE

PLASTIC PIPE

ABS Pipe and valve

PLASTIC PIPE

ABS Pipe and valve